Over two million tests are performed every month on over 100 BISS supplied shock absorber test systems with practically all global manufacturers. The evolution of superior shock absorber test technology involved many technological innovations, some of which impacted the entire BISS range of test equipment. The shock absorber industry now has the benefit of yet another important innovation named ’Single cycle peak velocity testing’.

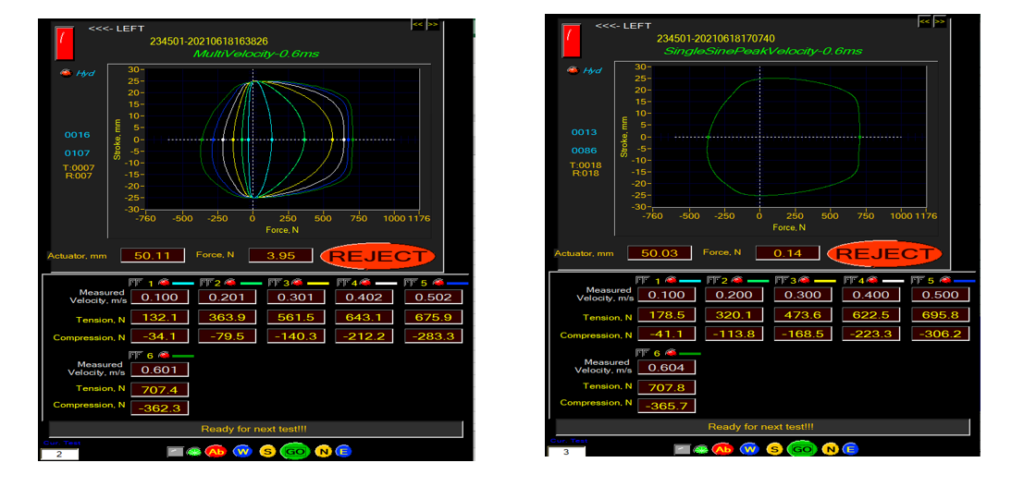

Available cycle time for production line QC testing is restricted to between 7 to 20 seconds depending on part type. A typical shock absorber for its evaluation of damping characteristics needs to be tested at multiple velocities, e.g., 0.1 m/s, 0.3 m/s, 0.5 m/s, 0.8 m/s and 1 m/s (on a test system rated to deliver max. velocity of 1 m/s). Latest BISS software solution extracts damping force readouts for all these velocities from just a single stroke of the shock absorber. The dramatic reduction in test cycle time allows manufacturers to boost production in this highly competitive market.